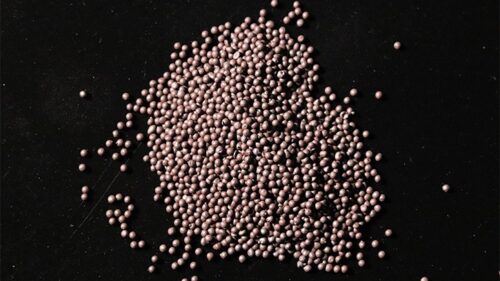

Glass beads, or glass bead abrasives, are most often used in general maintenance and blast cleaning processes. Blasting with glass beads allows the user to clean work pieces without significant surface removal. Due to its spherical shape, glass beads are also used in some peening applications. The shape also lends to a slow break down allowing for multiple turns and impacts.

The shape of glass beads allows for a four-step process in one application because they can clean, finish, peen, and in some cases even deburr. That combination provides a controlled and unique surface finish when compared to other common blasting abrasives. It leaves a nice, bright, satin finish on metallic surfaces.

The wide range of sizes available in glass beads allows for a variety of surface finishing and cosmetic textures. Glass beads are also chemically inert and will not leave contamination, or residue, on surfaces.

Applications:

- Cosmetic and satin finishing

- Blast cleaning when metal removal from work piece is of concern

- Mold cleaning

- Automotive restoration

- Light to medium peening of metal parts to reduce fatigue

- Carbon or heat treat scale removal

Physical Characteristics:

- Round shape

- 5-6 on the Mohs hardness scale

- Also available in mil spec, or military specification, sizing

- Bulk density is approximately 100 lbs. per cubic foot

SurfacePrep is a supplier of glass bead abrasives, offering a wide variety of glass bead blasting media. Contact us today to request a quote.